Offshore Welding Vietnam is increasingly recognised as a strategic manpower source for European companies engaged in oil & gas exploration, shipbuilding, and offshore renewable energy. The combination of highly trained welders, adaptability to demanding marine environments, and competitive costs makes Vietnamese professionals an attractive choice for contractors struggling with labour shortages in the EU.

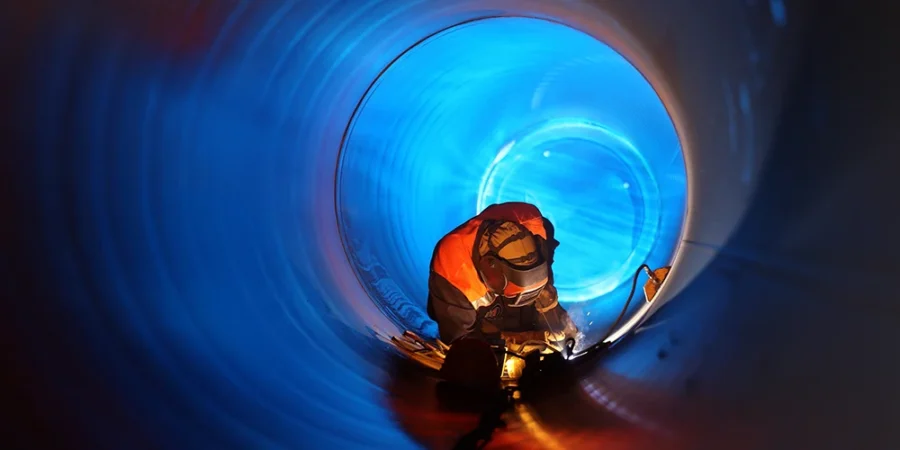

From welding high-pressure pipelines on a North Sea platform to assembling the transition pieces of an offshore wind turbine in Denmark, Vietnamese offshore welders are proving their value in projects where quality, safety, and deadlines are critical.

Offshore Welding in Europe – Key Sectors

Oil & Gas Platforms

Europe’s offshore oil & gas sector remains a cornerstone of its energy supply. Platforms in the North Sea, Barents Sea, and Mediterranean require welders capable of:

-

Performing 6G and 6GR welding on risers, flare towers, and process piping.

-

Working with corrosion-resistant alloys such as Inconel, duplex stainless steel, and titanium.

-

Meeting ASME IX, ISO 9606, and EN 287 standards.

Shipbuilding and Marine Engineering

Shipyards in Poland, Romania, Finland, and Spain continue to produce vessels ranging from LNG carriers to naval frigates. Offshore welders in this sector often handle:

-

Submerged Arc Welding (SAW) for hull construction.

-

Flux-Cored Arc Welding (FCAW) for large steel structures.

-

Compliance with classification society rules such as DNV, ABS, and Lloyd’s Register.

Offshore Wind Energy

Europe’s offshore wind capacity is expanding rapidly, driven by decarbonisation targets. Welders are needed for:

-

Fabricating monopiles, transition pieces, and jacket foundations.

-

Using low-hydrogen processes to minimise cracking in thick sections.

-

Performing installation support offshore, often in challenging sea conditions.

Why Offshore Welding Vietnam Is Competitive

-

Specialised Training for Marine Environments

Vietnamese offshore welders receive dual training in welding techniques and offshore survival skills, including BOSIET, H2S safety, and confined space procedures. -

Internationally Recognised Certifications

Common qualifications include:-

ISO 9606-1 and ISO 9606-2.

-

AWS D1.1/D1.5 for structural applications.

-

EN ISO 15614 WPS approvals.

-

-

Cultural and Operational Adaptability

Experience in mixed-nationality crews and an understanding of European worksite expectations allow them to integrate quickly with minimal downtime. -

Performance in Harsh Conditions

Offshore welding often involves high humidity, salt exposure, and vibration from waves — all of which require stable technique and endurance.

Technical Competencies of Offshore Welding Vietnam

-

6G/6GR Pipe Welding – Vital for platform risers and subsea spool pieces.

-

TIG (GTAW) – For root passes and high-specification alloy welding.

-

FCAW – High productivity in heavy steel sections, even in windy conditions.

-

SAW – Efficient for long seams in hulls and platform decks.

-

Hyperbaric Welding Awareness – Knowledge of principles for subsea repair, even if not saturation diving certified.

Offshore Oil & Gas vs Offshore Wind – Technical Differences

While both sectors require precision and durability, their welding demands differ:

| Aspect | Oil & Gas | Offshore Wind |

|---|---|---|

| Materials | Duplex stainless, Inconel | Carbon steel, weathering steel |

| Weld Thickness | Often >40mm | Typically 25–50mm |

| Environment | Platform or subsea | Yard fabrication + sea installation |

| Inspection | NDT + hydrotest | NDT + fatigue testing |

Corrosion Prevention in Marine Welding

Corrosion is the most persistent threat to offshore structures. Vietnamese offshore welders are trained in:

-

Selecting filler metals compatible with marine-grade alloys.

-

Applying post-weld heat treatment where required.

-

Coordinating with coating specialists for cathodic protection and epoxy finishes.

Case Study 1 – North Sea Gas Platform Upgrade

Client: Engineering contractor in Aberdeen.

Scope: Replace corroded sections of process piping.

Outcome:

-

12 Vietnamese welders deployed.

-

96% first-pass weld acceptance.

-

Project delivered two weeks ahead of schedule.

Case Study 2 – Offshore Wind Jacket Fabrication, Netherlands

Client: Renewable EPC specialist.

Scope: Weld 32 jacket foundations for a wind farm.

Outcome:

-

No rework required on major joints.

-

Welders adapted to new WPS within 48 hours.

Case Study 3 – LNG Carrier Construction, Poland

Client: Shipyard building dual-fuel LNG carriers.

Scope: Fabrication of cryogenic piping and hull assemblies.

Outcome:

-

All welders met Lloyd’s Register inspection criteria.

-

Work completed in line with launch schedule.

Recruitment Process at LabourLink Vietnam

LabourLink does not keep welders idle; sourcing begins after client confirmation:

-

Requirement Gathering – Define processes, materials, and offshore conditions.

-

Candidate Sourcing – From nationwide networks of certified welders.

-

Trade Testing – On-site or recorded to client specifications.

-

Deployment – Handling visas, travel, and induction.

Economic and Strategic Benefits

-

Lower Total Labour Costs – Up to 25% savings compared to EU hires.

-

Reduced Turnover – High completion rates for long-term offshore projects.

-

Increased Productivity – Stable weld quality in high-pressure environments.

Future Skills Development

As Europe moves towards greener energy, Offshore Welding Vietnam is preparing welders for:

-

Robotic welding systems used in offshore fabrication yards.

-

New materials for hydrogen platforms and floating solar units.

-

Advanced NDT techniques for predictive maintenance.

Further Reading

Contact LabourLink Vietnam

📧 Email: info@labourlinkvn.com

📱 WhatsApp: +84 913 338 588