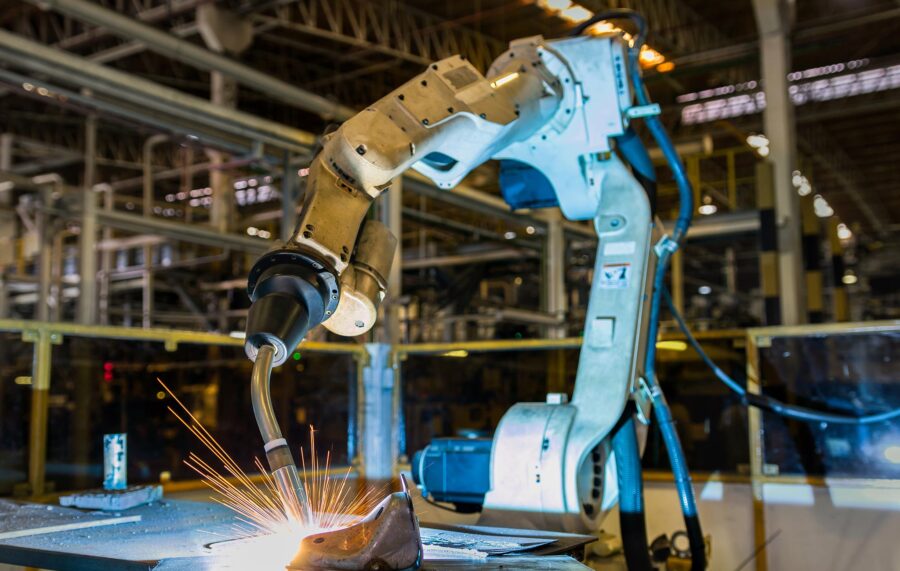

Robotic Welding Vietnam is emerging as a vital source of skilled automation talent for European manufacturers facing rising demand, labour shortages, and increasingly strict quality requirements. The European Union’s industrial strategy is moving rapidly towards smart manufacturing and automated welding systems, yet the availability of qualified operators remains a bottleneck.

From automotive assembly lines in Germany to offshore platform fabrication in the Netherlands, Vietnamese technicians are now part of the solution — combining strong welding foundations with programming and maintenance capabilities for leading robotic welding brands.

Automation Trends Driving Demand for Robotic Welding in Europe

The European manufacturing sector is in the midst of a structural shift. Several factors are pushing companies to invest heavily in robotic welding systems and skilled operators:

-

Acute Skilled Labour Shortages

Traditional manual welders are in short supply across the EU. While automation fills part of the gap, robotic systems cannot run themselves — they need human operators to set parameters, load materials, monitor quality, and carry out maintenance. -

Stringent Quality Standards

In aerospace, automotive, energy, and marine industries, welds must meet microscopic tolerances. Robots deliver consistency, but skilled operators ensure those tolerances are achieved across varying materials and joint geometries. -

Economic Competitiveness

Asian and North American manufacturers have already integrated advanced automation. For the EU to compete globally, scaling up robotic welding capacity is essential. -

Customisation Needs

Unlike high-volume consumer goods, EU manufacturing often requires flexibility — welding robots must be reprogrammed for bespoke or small-batch projects. Skilled operators from Robotic Welding Vietnam are trained to adapt quickly to such changes.

Manual Welding vs. Robotic Welding – Why Operators Are Still Critical

Although automation is expanding, the idea that robots replace human welders entirely is misleading. In reality, robotic welding creates a new kind of skilled role: the welding-robot operator-technician.

-

Programming and Path Optimisation

Operators input weld paths, arc parameters, and movement sequences into robot controllers. -

Fixture and Material Preparation

Poor alignment or contamination still leads to defective welds — human oversight is essential. -

Inspection and Quality Control

ISO 5817-compliant inspections, whether visual or via NDT, require trained eyes. -

Maintenance and Troubleshooting

Downtime in automated lines is costly. Operators trained in preventive maintenance keep equipment running efficiently.

Vietnamese technicians are trained in both traditional welding processes (MIG/MAG, TIG, FCAW) and robotic operation, making them uniquely suited for these hybrid roles.

Technical Competencies of Robotic Welding Vietnam Operators

LabourLink Vietnam’s recruitment process ensures that candidates possess:

-

Multi-Process Welding Skills – MIG/MAG for high-volume work, TIG for precision jobs, FCAW for heavy-gauge steel.

-

Brand-Specific Robotic Programming – ABB, KUKA, FANUC, Panasonic, and Yaskawa systems.

-

Material-Specific Knowledge – Aluminium, stainless steel, carbon steel, and exotic alloys.

-

Quality Assurance Expertise – Familiarity with ISO 5817, EN 1090, and IATF 16949 standards.

-

Preventive Maintenance Capability – Torch cleaning, wire feed system calibration, and coolant system checks.

-

Health and Safety Compliance – Machine guarding, lockout/tagout, and CE safety standards.

Industry Applications in the EU

Automotive Production

European automotive plants are integrating robotic welding at scale:

-

High-Speed Spot and MIG Welding for car bodies.

-

Frame and Chassis Assembly with precision and repeatability.

-

Battery Enclosure Fabrication for electric vehicles.

Shipbuilding and Offshore Fabrication

-

Long seam welds on ship hull panels.

-

Hybrid workflows where robots handle straight seams and humans manage complex joints.

-

Corrosion-resistant welding for marine environments.

Aerospace and Aviation

-

Thin-Wall Alloy Welding with TIG for minimal distortion.

-

Multi-axis robotic arms handling intricate geometries.

Structural Steel Manufacturing

-

Automated girder and beam welding for infrastructure projects.

-

Integration with CNC cutting lines for streamlined output.

Comparison of Major Robotic Welding Brands and Vietnamese Operator Expertise

Vietnamese robotic welding operators are familiar with the most widely used systems in the EU:

| Brand | Strengths in EU Manufacturing | Vietnamese Operator Expertise |

|---|---|---|

| ABB | High-precision welding, easy integration with vision systems. | Experienced in programming seam tracking and adaptive welding. |

| KUKA | Flexible multi-axis arms for complex projects. | Skilled in reprogramming for custom geometries. |

| FANUC | Popular in automotive with robust MIG capability. | Efficient in high-volume frame and chassis welding. |

| Yaskawa | Strong in arc welding for heavy industry. | Operators trained in both welding and material handling applications. |

| Panasonic | Compact cells suited for smaller production lines. | Adaptable to mixed manual-robotic workflows. |

Case Study 1 – Automotive Frame Welding in Germany

Client: German EV manufacturer

Scope: FANUC MIG welding cells for aluminium chassis.

Process: Operators trained in EV-specific welding in Vietnam before deployment.

Outcome:

-

12% reduction in cycle time.

-

8% decrease in weld defects.

-

Full compliance with IATF 16949.

Case Study 2 – Offshore Structure Fabrication in the Netherlands

Client: Offshore engineering contractor

Scope: ABB robotic FCAW welding for platform modules.

Process: Operators fine-tuned programmes for thick-gauge steel variation.

Outcome:

-

96% first-pass inspection rate.

-

Project delivered ahead of schedule.

Training and Certification Pathways in Vietnam

Vietnam’s technical schools and private institutes, in cooperation with export agencies, deliver:

-

Robotic Programming Modules tailored to EU equipment brands.

-

Material Handling and Preparation Skills to ensure weld quality.

-

International Welding Certification (ISO 9606, EN 287).

-

Pre-Departure Orientation covering EU workplace safety, culture, and communication.

Only candidates who pass both trade testing and client-specific evaluations are shortlisted. LabourLink Vietnam does not maintain idle manpower — recruitment begins only after receiving exact client requirements.

ROI Analysis – Why the EU Benefits from Robotic Welding Vietnam

Hiring Vietnamese robotic welding operators delivers measurable returns:

-

Reduced Downtime – Preventive maintenance cuts stoppages.

-

Faster Ramp-Up – Operators adapt quickly to EU factory protocols.

-

Lower Recruitment Costs – Compared to domestic hires, sourcing from Vietnam can save up to 30% in total labour cost.

-

Quality Consistency – Lower rework rates improve profitability.

Over a 3-year equipment lifecycle, the productivity gains from skilled operators can offset the entire cost of recruitment and relocation.

Future Outlook – Automation with a Human Edge

Automation will continue to reshape EU manufacturing, but it will not eliminate the need for skilled people. The operators coming from Robotic Welding Vietnam represent a blend of hands-on welding skill and advanced automation capability — exactly what Europe’s competitive industries require.

Further Reading on Welding Solutions from Vietnam

If you found this article useful, you may also want to explore:

For more insights, visit our News Section.

Contact LabourLink Vietnam

📧 Email: info@labourlinkvn.com

📱 WhatsApp: +84 913 338 588