The Rise of Underwater Welders Vietnam in Global Projects

Underwater welders Vietnam are increasingly recognised as a vital labour source for the offshore industry. These professionals combine commercial diving with advanced welding, creating a workforce that delivers precise subsea repairs under extreme conditions. Their growing reputation stems from a mix of strong technical training, adaptability, and cost efficiency.

Core Skills of Vietnamese Underwater Welders

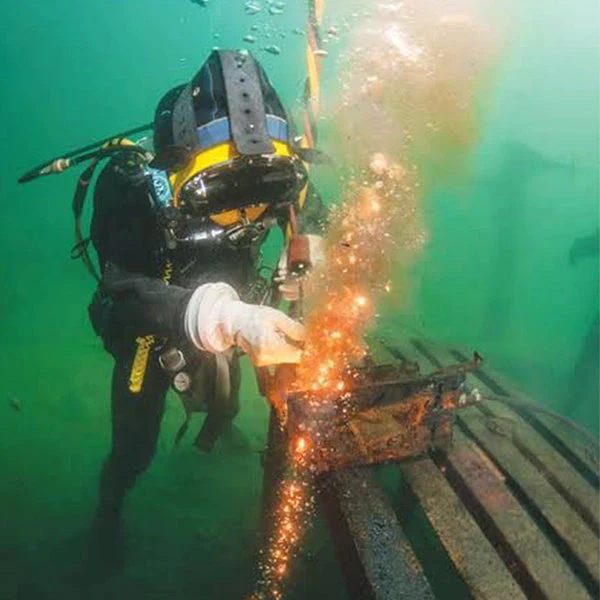

Unlike surface welders, Vietnamese underwater welders master two demanding disciplines: welding and diving. They train in manual metal arc (MMA), flux-cored arc (FCAW), and gas tungsten arc (TIG) processes, while simultaneously learning diving physiology, decompression schedules, and emergency protocols. This dual expertise enables them to weld in wet conditions with limited visibility, as well as in hyperbaric dry chambers at depths beyond 100 meters.

Their skill set allows them to handle a range of repairs, from ship hull maintenance to subsea pipeline welding. Many underwater welders Vietnam also specialise in cutting techniques, using oxy-arc or plasma torches to remove corroded sections before re-welding. This combination of welding and cutting proficiency makes them indispensable to offshore contractors.

Training and Certification of Underwater Welders in Vietnam

Becoming an underwater welder in Vietnam requires structured progression. Candidates start with standard certifications like ISO 9606 or ASME IX in welding. They then pursue commercial diving certifications aligned with IMCA or ADC International standards. Advanced training takes place in hyperbaric chambers, where welders simulate working at depth, experiencing both wet welding and dry chamber welding.

This layered training system ensures Vietnamese underwater welders can adapt to international projects in Europe, the Middle East, and the Asia-Pacific. Their certificates are widely recognised, which lowers the barriers for employers seeking qualified manpower.

Safety Standards Observed by Vietnamese Offshore Welders

The profession of underwater welding ranks among the most dangerous in the world. Risks include electric shock, decompression sickness, and hypothermia. Vietnamese training centres place heavy emphasis on safety awareness. Welders are drilled in proper electrode handling, communications with surface teams, and step-by-step decompression schedules.

On active projects, every dive is planned with supervisors, standby divers, and medical personnel on alert. This culture of safety makes underwater welders Vietnam highly reliable. For global contractors, reduced accident rates translate directly into fewer delays and lower insurance costs.

Types of Underwater Welding Vietnamese Workers Perform

Vietnamese underwater welders are versatile, able to switch between techniques depending on project requirements:

-

Wet Welding: Directly performed underwater using waterproof electrodes. Though more exposed, it allows fast repairs on pipelines and ship hulls.

-

Dry Hyperbaric Welding: Conducted in a sealed chamber at depth, giving welders a dry environment and producing higher-quality welds for critical structures.

-

Underwater Cutting: Often a precursor to welding, cutting involves removing damaged metal using oxy-arc or plasma systems.

By mastering these techniques, underwater welders Vietnam can serve industries from oil & gas to renewable offshore wind farms.

Cost Benefits of Hiring Vietnamese Welders

For international companies, hiring Vietnamese underwater welders delivers measurable savings. Daily wage rates remain significantly lower compared to Western markets, while skill levels remain competitive. Beyond wages, Vietnamese welders also adapt quickly to work-site conditions, which reduces mobilisation times.

This balance of affordability and quality explains why more European and Middle Eastern companies are requesting underwater welders Vietnam for contracts. The cost efficiency is especially critical for large maintenance campaigns, where labour costs form a major portion of the budget.

Offshore Industries Relying on Vietnamese Underwater Welders

The demand for Vietnamese underwater welders spans multiple industries:

-

Oil & Gas Platforms: Repairing corroded risers, subsea pipelines, and structural supports.

-

Shipping and Marine Transport: Performing hull inspections, propeller welds, and underwater retrofits without dry-docking.

-

Harbours and Ports: Welding on piles, docks, and underwater foundations to keep trade hubs operational.

-

Renewable Energy: Supporting offshore wind and tidal installations where underwater structures require routine welding and inspection.

By engaging underwater welders Vietnam, these industries avoid prolonged downtime, saving millions in lost productivity.

Daily Work of a Vietnamese Welders

A typical shift for an underwater welder in Vietnam working offshore begins with a detailed safety briefing. Welders inspect equipment, electrodes, and diving suits before entering the water. Once submerged, they navigate low-visibility environments, using touch and guided lighting to position electrodes.

Tasks might include grinding surfaces clean, executing multi-pass welds, or sealing leaks in high-pressure pipes. Communication with surface teams remains constant, ensuring weld quality and diver safety. Each dive concludes with a decompression schedule, followed by surface inspection of weld quality.

This structured routine highlights the discipline and professionalism of Vietnamese underwater welders, which global contractors highly value.

Technological Tools Supporting Vietnamese Underwater Welders

While manual skill remains central, underwater welders Vietnam increasingly integrate technology. Remote Operated Vehicles (ROVs) assist in pre-weld inspections. Ultrasonic testing equipment verifies weld integrity without lifting structures from the water. Some projects even involve hybrid operations, where welders perform manual welding while ROVs capture real-time video for quality assurance.

By blending traditional craft with modern tools, Vietnamese welders stay competitive with international peers.

Demand for Underwater Welders Vietnam in Europe and the Middle East

The North Sea, with its ageing offshore infrastructure, has become a major hub for Vietnamese underwater welders. European contractors frequently request them for pipeline repair campaigns. Meanwhile, Middle Eastern oil giants employ them to maintain offshore fields in the Persian Gulf.

These regions prefer Vietnamese underwater welders because they combine lower cost with high reliability. Many return for multiple contracts, building long-term trust with global clients.

Career Growth for Vietnamese Workers

The profession is not only demanding but also rewarding. Experienced underwater welders Vietnam often progress into supervisory positions such as dive supervisors or welding inspectors. Others move into project management roles, overseeing entire offshore repair operations.

This career trajectory ensures that hiring Vietnamese underwater welders provides companies not just immediate labour, but also long-term expertise for future projects.

Challenges Faced by Vietnamese Underwater Welders

Despite their skills, Vietnamese underwater welders face challenges such as extended time away from home, harsh working conditions, and physical strain. Offshore shifts can last weeks, requiring strong mental resilience. Employers who understand these challenges often provide rotation schedules, psychological support, and modern equipment to retain workers.

Addressing these issues ensures higher retention rates and sustained productivity.

Explore More Articles on Vietnam Manpower Welder

📩 Contact us at info@vietnammanpowerwelder.com

📞 WhatsApp: +84913338588