In the context of European industrial development, particularly across sectors like energy, shipbuilding, food processing, and petrochemicals, workforce compliance is no longer optional. When hiring international labour, especially welders, employers are not simply recruiting hands—they are integrating high-risk operations into their certified quality frameworks. That’s why Vietnam welding certification for Europe has become a vital checkpoint for technical directors, HR planners, and procurement leads.

Vietnamese welders have gained global attention for their precision, work ethic, and versatility. But for European employers, the true value lies in the welders’ certification pedigree. Whether it’s an ISO standard, ASME code, or EN guideline, a welding qualification must reflect the expectations of the receiving country and project type.

Why Certification Matters for EU Employers

Welding is a safety-critical function. In the EU, regulatory environments are strict. Whether a weld fails in a food-grade pipe or a pressure vessel seam, the consequences range from financial loss to human risk. Certification is the first filter to mitigate that risk.

European employers must ensure their Vietnamese welding hires are:

- Certified under accepted international codes

- Tested by recognised third-party bodies

- Auditable through proper documentation

- Aligned with material and positional requirements

Vietnam welding certification for Europe means more than a piece of paper—it is the operational proof that your manpower is legally and technically fit for EU job sites.

Most Recognised Welding Standards for EU Deployment

Vietnamese welders prepared for European contracts typically hold some or all of the following certifications:

1. ISO 9606-1

The international standard for the qualification of welders working with metallic materials.

- Applicable to steel welders

- Recognised throughout the EU

- Essential for pressure piping, structural, and general fabrication

2. ASME Section IX

American standard, widely accepted by multinational contractors across Europe.

- Common in oil, gas, power plant, and vessel work

- Often used in EPC and international supplier chains

3. EN 287 (now phased into ISO 9606)

Still cited in legacy contracts, particularly older EU projects.

- Welders trained in EN 287 format can easily transition to ISO 9606 standards

4. PED (Pressure Equipment Directive) Alignment

For jobs that fall under the European Pressure Equipment Directive.

- Welders must be qualified under a system reviewed by a notified body

These certifications cover not just the skill of making a weld, but understanding of joint configuration, material matching, and essential safety parameters.

How Welders in Vietnam Are Trained and Certified

Vietnam’s top vocational institutes, private training centres, and recruitment partners have evolved beyond basic fabrication training. Welders bound for EU projects undergo:

- Theory training in welding principles and metallurgy

- Hands-on practice in 6G, overhead, vertical-up/down, and pipe positions

- Destructive and non-destructive test prep

- WPS (Welding Procedure Specification) interpretation

- Simulated worksite environments

- Third-party witnessing and documentation

Many welders are certified in Vietnam by internationally accredited testing bodies or undergo requalification on arrival in Europe under project-specific guidelines.

Certification vs Qualification: What Employers Must Understand

European employers often confuse certification with qualification. Here’s the key distinction:

- Certification is issued by a testing body (e.g., after passing ISO 9606-1 test).

- Qualification refers to the employer’s validation that the welder is suitable for their specific WPS and job scope.

So, while a welder may arrive with valid ISO certification, they may still require project-specific qualification tests before being put to work.

Understanding this nuance is essential to planning timelines and onboarding schedules.

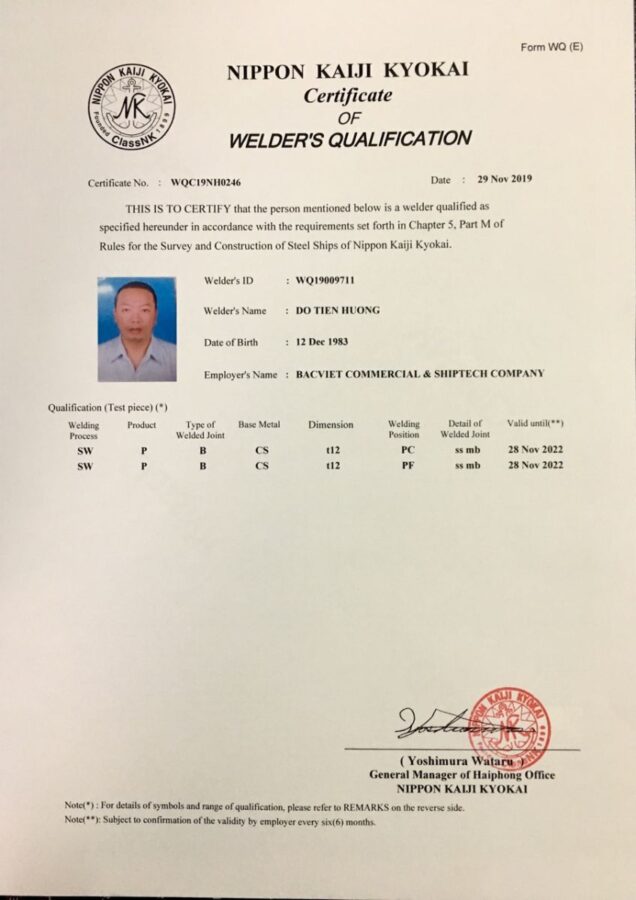

What Documents Should You Expect?

When hiring Vietnamese welders for EU projects, employers should request a complete welder certification package that includes:

- Copy of valid ISO 9606-1 or ASME IX certificate

- Welder ID with photo

- WPS used during certification test

- Test result sheet and third-party verification

- NDT reports (where applicable)

- Weld map samples (if available)

This ensures that the welder’s competence is traceable, auditable, and consistent with project requirements.

Labour Link Vietnam’s Role in Certification Assurance

At Labour Link Vietnam, welding candidates are:

- Pre-screened with internal 6G and position-specific weld tests

- Enrolled in external testing centres aligned with ISO/ASME standards

- Documented digitally for transparency and verification

Before deployment, each welder is issued a profile that includes:

- Certification scans

- Test video archive (if required)

- Site behaviour record

- Health and PPE compliance form

Our coordination with EU-based clients ensures that project-specific requalification can also be arranged pre-arrival or upon landing, depending on jurisdiction.

Matching Certification to Sector-Specific Needs

Different sectors require different welding competencies and oversight. Vietnamese welders are matched accordingly:

- Pharma and food: Stainless TIG welders with hygiene handling certification

- Oil & gas: SMAW/GTAW with ASME IX and PED alignment

- Shipbuilding: Multi-position MIG/TIG with steel & aluminium experience

- Power plants: Pipe welders with 6G + radiographic-quality welds

- General fabrication: MIG/MAG welders with structural fit-up skills

Each sector has embedded quality standards, and the Vietnam welding certification for Europe adapts accordingly.

Common Pitfalls Employers Should Avoid

- Assuming all certifications are valid EU-wide: Always verify issuing body recognition.

- Relying only on paper certification: Visual or trial welds should be part of onboarding.

- Failing to match WPS to certification scope: Don’t assign a 2G certified welder to a 6G job.

- Not budgeting for requalification: Build in 1–3 days for site-specific tests where required.

Labour Link Vietnam helps employers navigate these pitfalls by aligning candidate certification to actual job specs before deployment.

The Strategic Case for Certified Vietnamese Welders

When you hire certified Vietnamese welders, you don’t just gain skilled labour. You gain:

- Predictability in compliance audits

- Reduced onboarding time

- Lower weld rejection rates

- Fewer reworks and delays

- A consistent, renewable labour source

More importantly, your internal quality teams can focus on higher-value oversight, knowing that frontline welders are already aligned to required standards.

Ready to Source Certified Welders with EU-Aligned Credentials?

Vietnam welding certification for Europe is no longer a secondary issue—it’s the first question any responsible project manager must ask.

Let Labour Link Vietnam help you source, test, and deploy welders with the right credentials for your next industrial project. From ASME pipe work to ISO-compliant stainless steel joints, we ensure every credential is real, current, and relevant.

Contact us today for certification samples, welder CVs, or to arrange trial welding sessions tailored to your site needs.

Certified. Verified. EU-Ready. That’s Vietnam’s welding advantage.